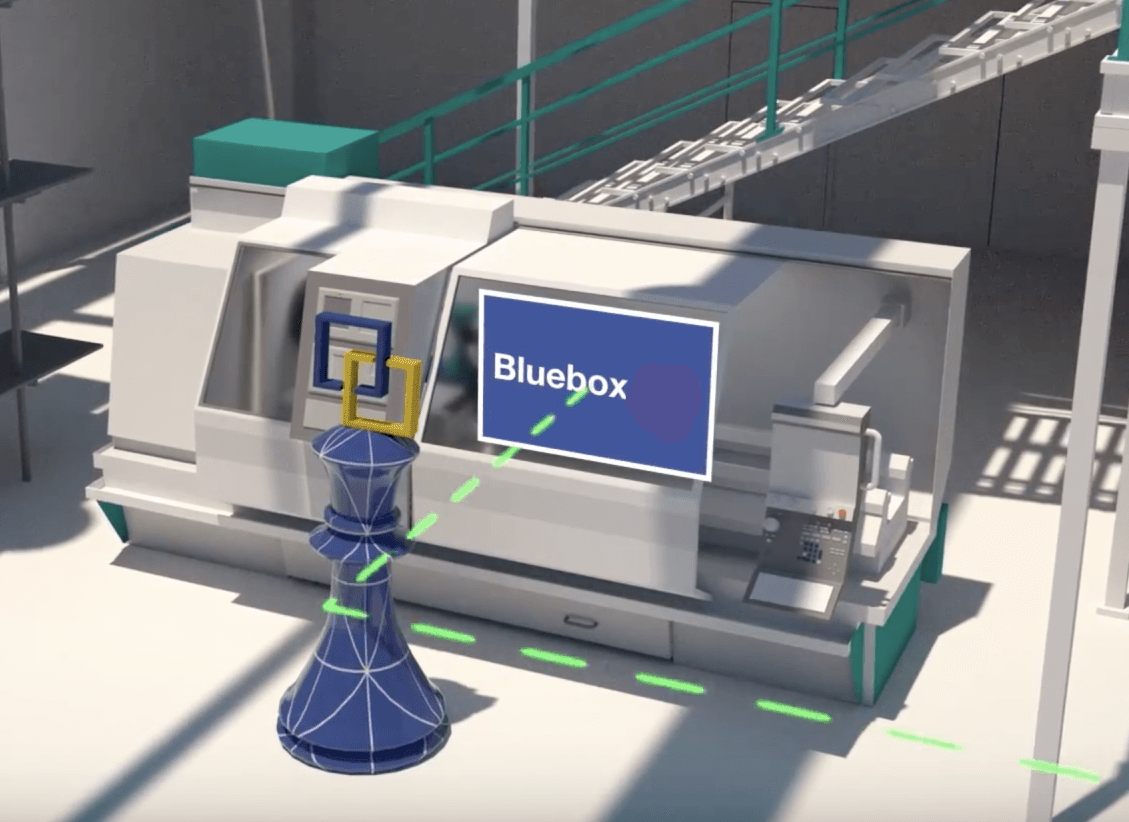

KauFe.Bluebox

- Keep it Simple & Efficient -

Transparency for your production processes

Process, energy or production data

Understanding data, unleashing potential

Significantly increase efficiency

Data specialists from KauFe Innovation

Eligible for funding through BAFA - BlueboxEnergy

simple

efficient

- Production data acquisition

- Data analysis and management

- Increased resource efficiency

- Energy management ISO 50001

- Optimization of waiting and setup time

- Increase quality rate

- Order and organizational planning

- and much more

unbeatable

- User access

- Number of signals and devices

- Number of machines

- Data volumes

- Number of data retrievals

- Backups and storage

- Licenses &Updates

- mobile versions

- Maintenance contracts

- Functional enhancements

- Interfaces

KaufFe Innovation - the expansion stages of the Bluebox

The Bluebox is currently divided into three levels. Level 1 is "descriptive analytics," the descriptive analysis in which insights into the current production status can be gained from historical and live data.

Level 2, the tower, incorporates diagnostic and predictive analytics. These analyses provide explanations for causes, effects, and interactions, and make predictions about future events. The focus here is on shop floor management and the continuous improvement process (CIP).

Level 3, the Datafacture, deals with "prescriptive analytics," or the analysis that mandates action. This involves concrete measures that can be taken in advance to prevent potential future problems. The focus here is on the development of AI (artificial intelligence), intelligent algorithms, machine learning, data science, and more.

General questions

Bluebox.SDI - the state-of-the-art and innovative solution